Parabolic Rolling Line

Product ID: CEG-PRL-LFDTSPS

Order Information

Name: Parabolic Rolling Line

Product ID: CEG-PRL-LFDTSPS

Optional Parts:

L: Loading and Arranging Machine

F:Walking Beam Furnace

D: Descaling Facility

T: Transfer and Feeding System

S: Straightening Machine

P:3-Position Hydraulic Presser and Assist Robot

S: Cooling Collection and Stacking Machine

Design

Loading and Arranging Machine

-

Little remaining magnetic after stacking. Stacking without disorder.

-

Stacking position adjustable. To adapt different heating requirements of leaf spring production.

-

Aligning stroke adjustable

-

Stacking and aligning motion does not interfere with walking beam furnace.

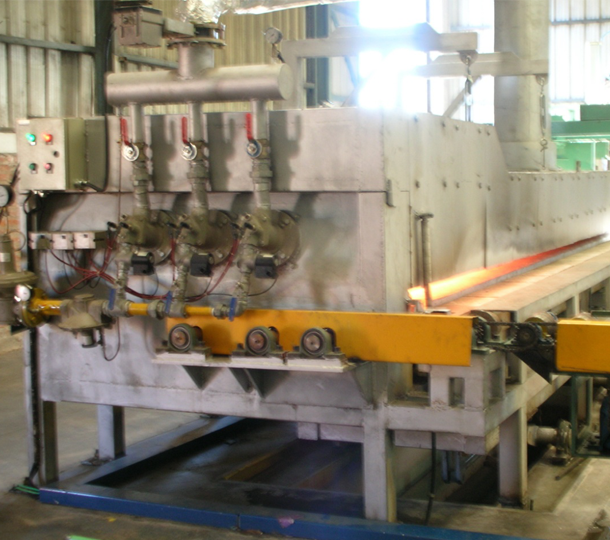

Walking Beam Furnace

-

Furnace equipped a heat exchanger. Combustion air can be heated using waste heat and improve energy efficiency.

-

There is preheating and heating zones in the furnace. The temperature of heating zones controlled by the controller.

-

Feeding machine cooperate with rolling machine.

-

Gas meter and pressure relief devices comply with relevant national standards

Descaling Facility

Transfer and Feeding System

-

Computer automatically calculates positioning length

-

Loading and unloading are synchronized

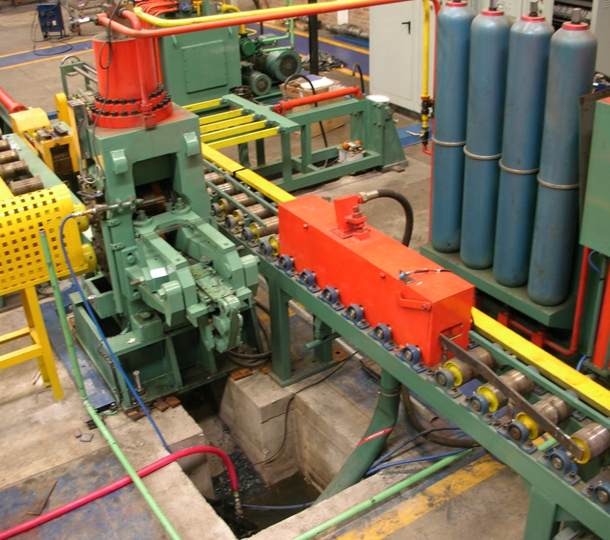

Parabolic Rolling Machine

Straightening Machine

-

The Heat Straightening Machine uses a parallelogram mechanism to maintain its ability to straighten the heated end spring leaf while the other side is cold.

-

Less indentation on the straightened side

3-Position Hydraulic Presser

Assist Robot

-

A 6-axis robot. It can catch the leaf spring for pressing processing.

-

The Specially designed hydraulic hand can provide a strong clamping force, and can run in a high temperature environment.

Cooling Collection and Stacking Machine

Number of layers per stack and number of leaves per layer can be set by PLC.

Specifications

Loading and Arranging Machine

|

Spring plate stack |

||

|

Length |

800-2500 |

mm |

|

Width, Max. |

700 |

mm |

|

Height, Max |

500 |

mm |

|

Weight of single layer, Max |

500 |

kg |

|

Allowed deviation in the longitudinal direction |

±5 |

mm |

|

Allowed deviation in the width direction |

±2 |

mm |

|

Conveyor line height |

250 |

mm |

|

Loadingperformance |

||

|

Magnetic chuck force |

10 |

kN |

|

Lifting height |

800 |

mm |

|

Horizontal moving distance |

1000 |

mm |

|

Layer pusher stroke |

≥400 |

mm |

|

Arranging performance |

||

|

Width of Arranging |

800 |

mm |

|

Arranging stroke |

0-800 |

mm |

Walk Beam Furnace

|

Spring plate |

||

|

Length, Max. |

2200 |

mm |

|

Length, Min. |

800 |

mm |

|

Width, Max. |

120 |

mm |

|

Width, Min. |

40 |

mm |

|

Thickness, Max |

62 |

mm |

|

Thickness, Min |

6 |

mm |

|

Heating Length, Max. |

950 |

mm |

|

Heating Length, Min. |

100 |

mm |

|

Heating performance |

||

|

Efficiency[1] |

3 |

ends/min |

|

Heating temperature, Max. |

1200 |

℃ |

|

Accuracy |

± 10 |

℃ |

|

Furnace |

||

|

Width of furnace chamber |

1050 |

mm |

|

Fuel[2] |

Natural gas |

|

|

Natural gas pressure |

6000 |

Pa |

|

Nominal gas combustion capacity |

960 |

kW |

|

Exhaust pipe |

14 |

m |

|

Walk-beam step |

||

|

Cycletime (Adjustable) |

10-60 |

s |

|

Stroke (Adjustable) |

40-140 |

mm |

|

Motor power |

||

|

Hydraulic station |

3 |

kW |

|

Air fan |

7.5 |

kW |

[1]For heating length of 600mm with cross section of 16×90mm

[2]PARTY B select nature gas

Descaling Facility

|

Descaling Facility |

||

|

Water pressure |

25 |

Mpa |

|

Descaling rate |

≤20 |

sec/piece |

|

Water consumption |

2.5 |

L/piece |

|

Descaling efficiency |

≥90 |

% |

|

Electrical power |

7.5 |

kW |

Parabolic Rolling Machine

|

Rolling force |

||

|

Horizontal |

1000 |

kN |

|

Vertical |

100 |

kN |

|

Spring plate before rolling |

||

|

Length, Max. |

2200 |

mm |

|

Length, Min.(Auto feeding) |

800 |

mm |

|

Width, Max. |

120 |

mm |

|

Width, Min. |

40 |

mm |

|

Thickness, Max. |

62 |

mm |

|

Thickness, Min. |

6 |

mm |

|

Spring plate after rolling |

||

|

Length, Max. |

2800 |

mm |

|

Rolled length, Max |

1300 |

mm |

|

Thickness, Min |

2 |

mm |

|

Tolerance |

||

|

Width |

±0.5 |

mm |

|

±0.15 |

mm |

|

|

Rolling start position |

±1.5 |

mm |

|

Side straightness |

≤2 |

mm/m |

|

Forming |

||

|

Slope, Max. |

1:10 |

|

|

Passes per end |

1-10 |

passes |

|

Segments |

1-15 |

parts |

|

Segments shapes |

Straight Parabolic |

|

|

Rolling positioning |

Cold end positioning |

|

|

Production |

||

|

Efficiency[1] |

20-30 |

sec/end |

|

Motor Power |

||

|

Roller motor power |

37 |

kW |

|

Hydraulic motor |

30+30 |

kW |

[1]Rolling with 3 passes

Straightening Machine

|

Straightening performance |

||

|

Side curve of Straightening[1] |

≤1.5 |

mm/m |

|

10~30 |

sec/pc |

|

|

Indenter opening (jaws replaceable) |

≥150 |

mm |

|

Pressing force, Max. |

630 |

kN |

|

Size of spring plate |

||

|

Length, Max. |

2600 |

mm |

|

Width, Max. |

120 |

mm |

|

Thickness, Max. |

70 |

mm |

[1] From rolling start point add 100mm offset to end point

3-Position Hydraulic Presser

|

Size of leaf spring |

||

|

Length, Max. |

2800 |

mm |

|

Length, Min. |

800 |

mm |

|

Width, Max |

120 |

mm |

|

Width, Min |

40 |

mm |

|

Thickness, Max |

40 |

mm |

|

Thickness, Min |

6 |

mm |

|

Hydraulic Presser |

||

|

Work positions |

3 |

|

|

Distance between work positions |

600 and 700 |

mm |

|

Altitude ofslider |

800 |

mm |

|

Stroke of press head, Max. |

300 |

mm |

|

Altitude of workbench |

740 |

mm |

|

Pressing performance |

||

|

Pressure force |

2000 |

kN |

|

Press speed |

0-150 |

mm/s |

|

Lift up speed |

0-300 |

mm/s |

Assist Robot

|

Robotic Arm |

||

|

Number of axes |

6 |

|

|

Positioning accuracy |

±0.2 |

mm |

|

Operating radius |

2702 |

mm |

|

Power |

5 |

kW |

|

Hydraulic Hand |

||

|

Width of Clamping, Max. |

120 |

mm |

|

Width of Clamping, Min. |

40 |

mm |

|

Weight of Clamping, Max. |

100 |

kg |

|

Hydraulic station |

||

|

Power |

4 |

kW |

Cooling Collection and Stacking Machine

|

Manipulator |

||

|

Clamping force |

10 |

kN |

|

Opening |

150 |

mm |

|

Lifting distance |

800 |

mm |

|

Horizontal moving distance |

1000 |

mm |

|

Spring plate stock |

||

|

Length, Max. |

2800 |

mm |

|

Length, Min. |

1000 |

mm |

|

Width, Max. |

700 |

mm |

|

Height, Max. |

500 |

mm |

|

Weight of single layer |

250 |

kg |

|

Tolerance |

||

|

End aligning tolerance |

±10 |

mm |